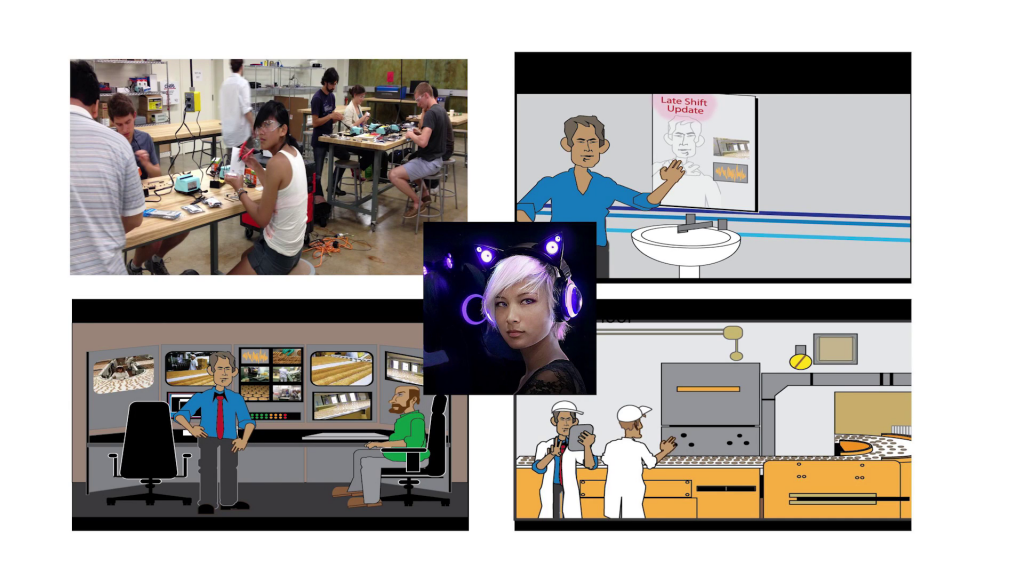

Good morning, everybody. I’d like to draw your attention to this book that I didn’t write. It’s by Klaus Schwab. On page three, it talks about the elements of the fourth industrial revolution, of velocity, breadth and depth, and systems impact. So, as my slides begin, what you’ll see is a group of my students working in a lab using 3D printing technologies, using advanced electronics, and using advanced open system software. Open system computer-aided design and computer-aided manufacturing software.

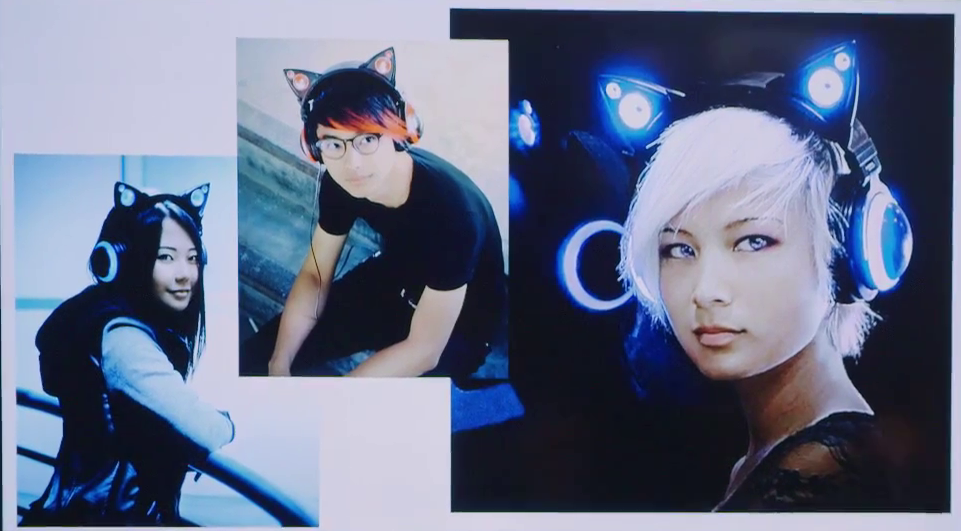

From that lab, an enormous velocity is being created for the students to come out of that lab. And I have to confess to my own surprise the kind of products that come from that group. Shown here, these cat earphones that came from that group. Basically that’s just karaoke that you can engage in with your friends.

On the left is Stella, in the middle is Colin, on the right-hand side is Nicole. Can you believe that that group, coming out of that lab in only eighteen months created a product that was sold by Brookstone, using these kind of 3D printers that you see in the top left?

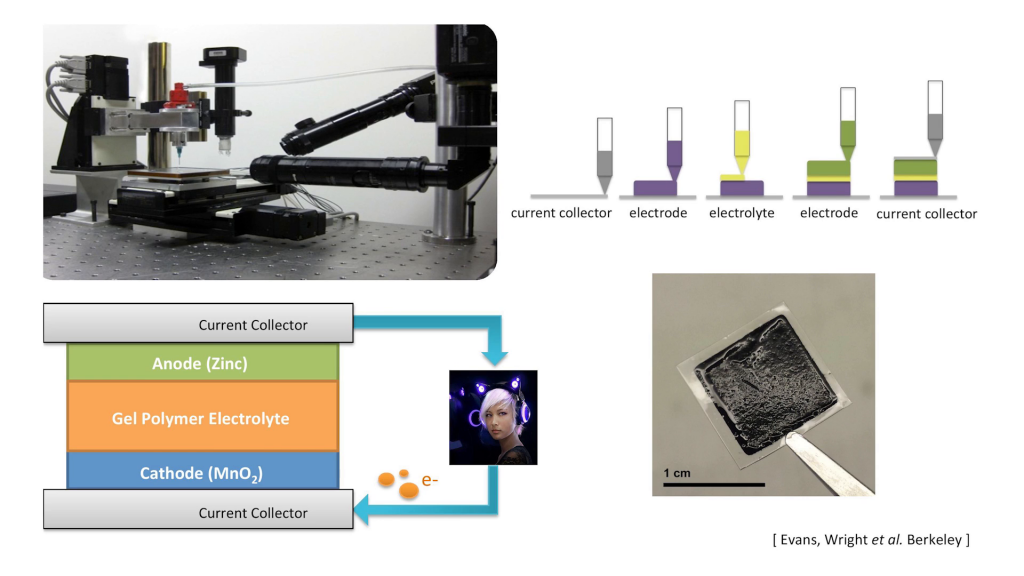

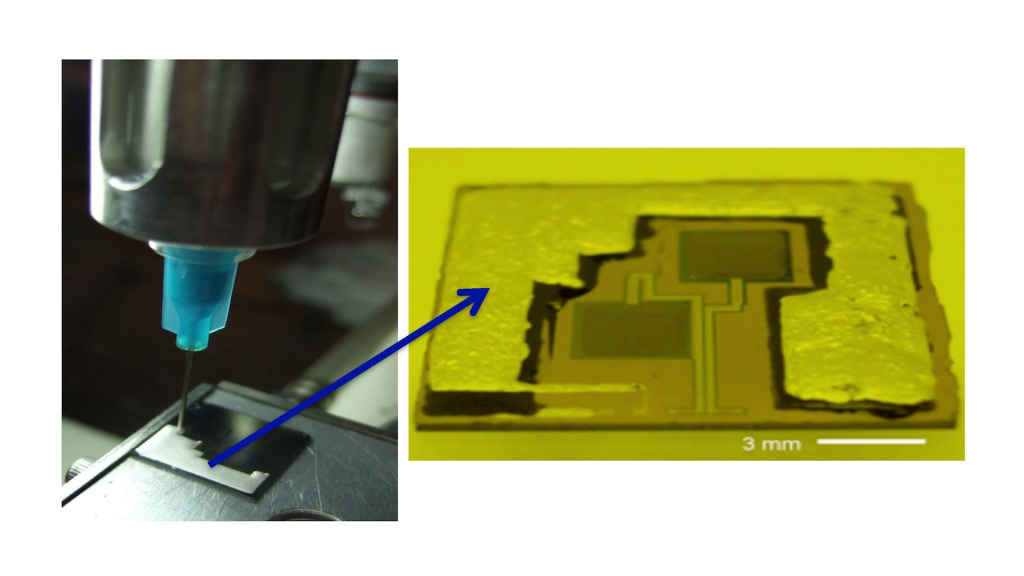

As we began this work in 1987, 1990, going through that period, 3D printers were pretty clumsy. But now, as shown in the bottom right, they’re faster, they’re cheaper, they’re much more precise and much more accurate. So, as we go clockwise in this slide, we go through the process now where we can actually print the chemicals for a battery. Shown in the bottom right, which is part of our new start-up called Imprint Energy, that’s being used for a variety of new products. And now, Nicole could print her own batteries to suit the design that she wants to create.

Now, going to the second part of my framed talk on the breadth and the depth, let’s look at the depth. The depth now is that we can not only print the battery shown there, but we can integrate it with the electronics shown on the bottom part of this slide. So, we have a battery system printing over the electronics.

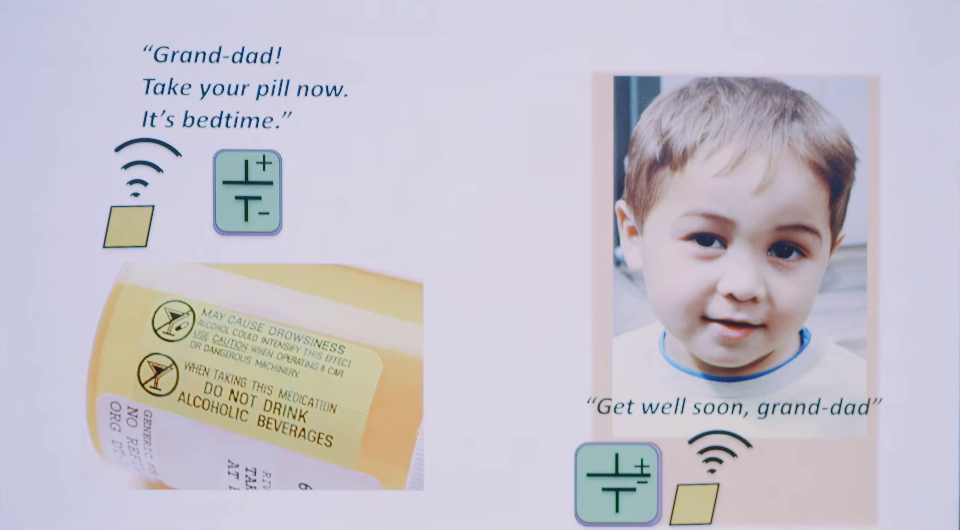

And my colleague Jim Evans, his grandson is shown on the right there, where we printed a greeting card for Jim when he was sick. And the card was able to sort of personalize the greeting to his grandfather, and even the pills that are shown on the left told Jim when he should take his nighttime medications. And so we have products now which have got these integrated processes.

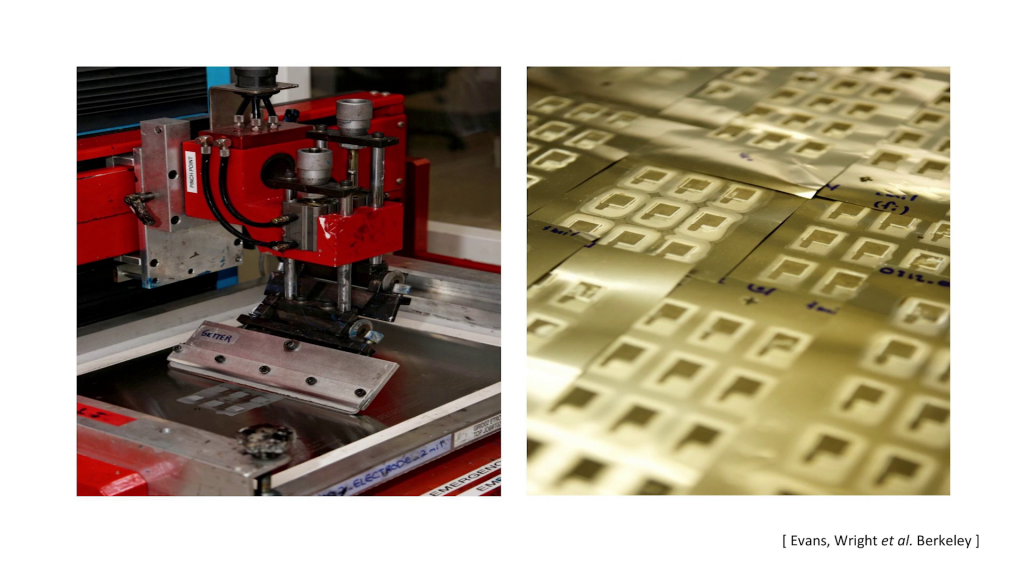

Coming to the breadth now, instead of the depth, we’re trying to create scale-up of these products to larger energy systems, which is the passion that we have in this meeting. Also, it’s manufacturing and it’s clean energy. These battery systems [shown] here in the printing device, and you can see some of our system is being printed there.

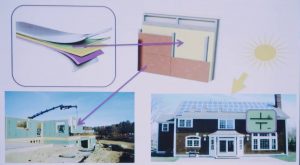

And now we’ve done the calculations to show that we can use traditional printing methods from another Cal campus, which is in the top slide, using the printing technology on the left. You’ll see my graduate student’s feet on the right there, where the first anodes of a zinc-based system are being printed out to create printed devices which we’re scaling in the future (This is the breadth of this.) through these panels, which ares similar to the Tesla vision of having printed panels around in your house to back up the solar energy that you’re going to collect from the sun. So there’s a wide variety of manufacturing techniques that are also being scaled.

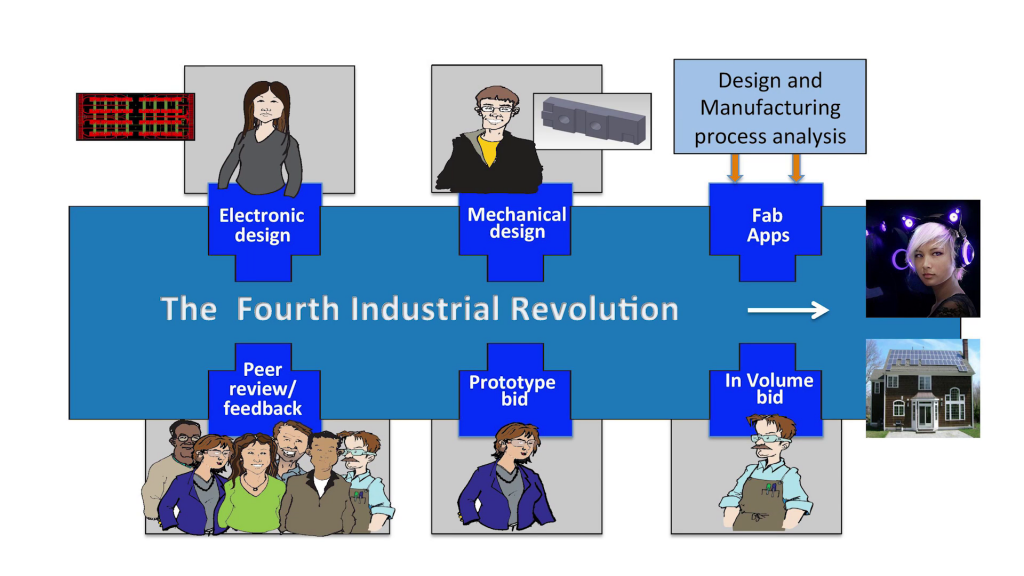

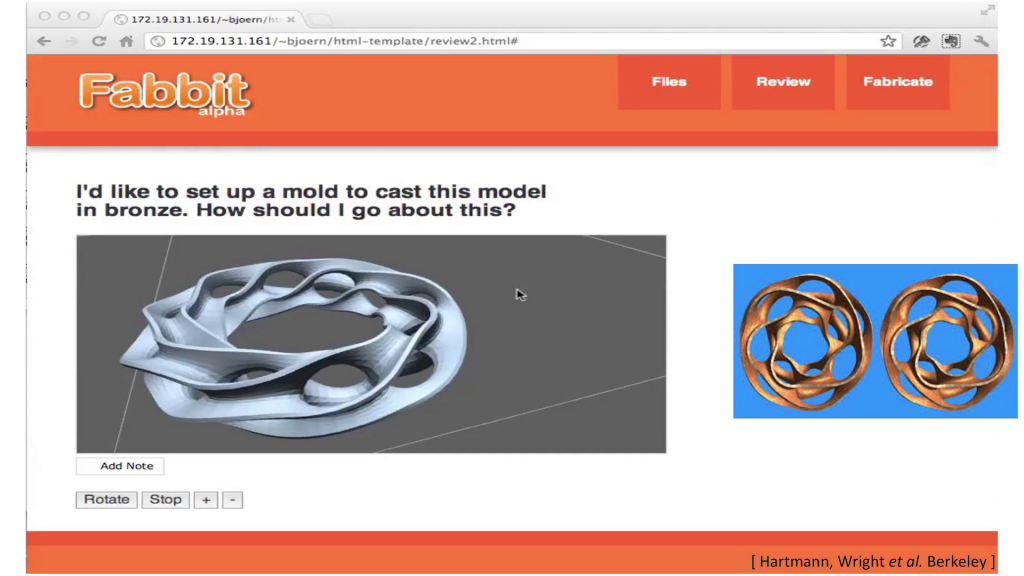

In the future… This is a very important slide. It shows my students towards the left of the slide. On the bottom right is a gentleman in a factory, and that factory could be anywhere. But the key element is in the very top right, these artificial intelligence apps that are telling my students, “Is this design that you made manufacturable?”

In this slide, students are making those earrings on the right. They need to make a mold. They don’t know anything about costing, they don’t know anything about injection molding. But they need and app to tell them whether the design they have is manufacturable in one piece or whether it needs to be split up into several pieces to get made. So, it’s the in-depth knowledge about manufacturing that with these AI techniques is being lifted up to the design environment.

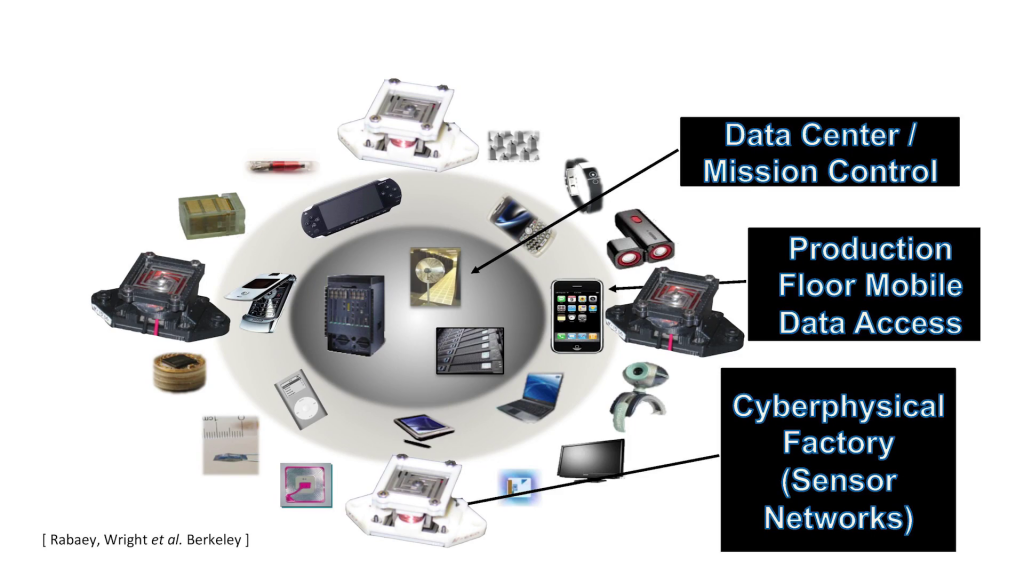

When we go to the factory now, the big design systems in the center of this slide are connected to the mobility in the factory. The Internet of Things are all over the factory machines. The factory machines now are connected to the main part of the factory, but as we go forward, also they’ll be connected to Nicole and the students in my lab.

When they finished the design, they’ll be able to tweak it according to those AI information techniques that come from the apps. They’ll be able to communicate with the factory, which could be on another side of the world, begin to see how their production gets made, and if necessary track their production as the production is going through. Just like you get an informational your FedEx parcel is on the way, Nicole will get information that our factory system is working smoothly and they’re getting feedback.

Maybe, if they need more or less of those components, when she wakes up in the morning she’ll go to her bathroom and then have a discussion with one of the factory personnel, maybe be on the other side of the world, telling her whether the production is going well, if the right number of components are being made. Hey, it’s the holiday season, too. We should ramp up to a larger number of components. And I want to do that, and make it connected to the IoT devices in the factory, to the factory personnel, and to the designers themselves.

This is very exciting, but the question I ask you to think about: We now have the opportunity [of] including the whole of the world in this activity. We want to make sure there’s growth around inclusivity. We want to make sure that everybody has access to this kind of system. At Berkeley, we believe it’s the educational route forward. There’s absolutely necessary…shown in my very first slides. We want to include all people. Maybe somebody that doesn’t have access to that manufacturing can really get onto the Internet and design something special, even like those earrings, a fairly simple device.

But at the same time, without the right education, people could get left behind. So, this fourth industrial revolution needs to include everybody. And that’s what I’d like to make part of my discussion. So, thank you. It’s great to be here. Thank you very much.

Further Reference

Paul K Wright faculty profile at the UC Berkeley site.