Our bridges, motorways, tunnels, and dams, and all the buildings that make up our infrastructure are vital to our society and economic growth yet we take them for granted. The shocking truth is that our infrastructure is crumbling beneath our feet. And this is costing us dearly, both in terms of money and carbon.

Now, most of our infrastructure is actually made up of a remarkable construction material, concrete. But concrete deteriorates, and for decades we have been neglecting its upkeep. It is now reaching a state of crisis. It will require huge amounts of money to upgrade it.

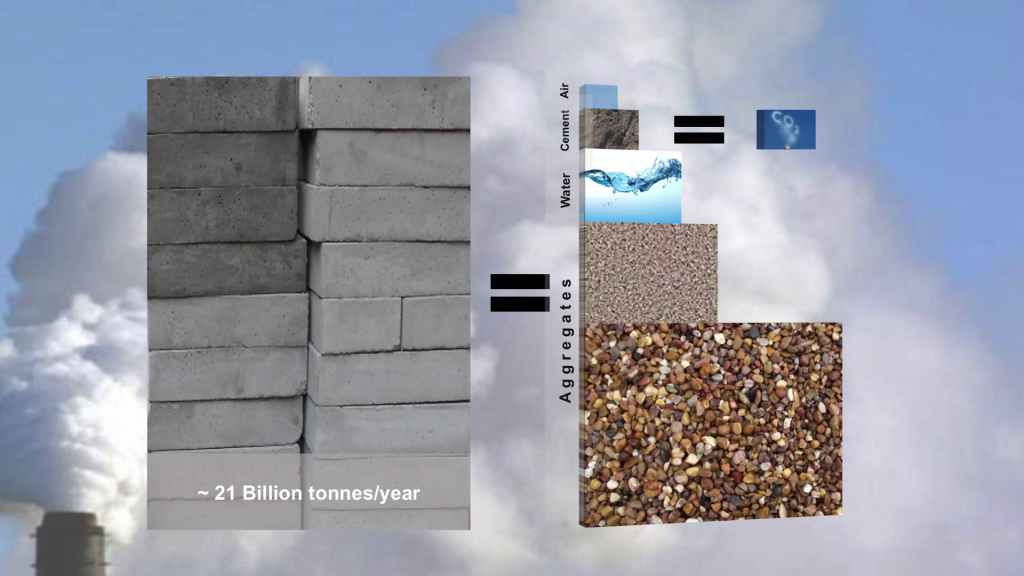

And we use so much concrete, around three tons for every person on the planet, per year. It is the second-most used substance on earth after water. It consumes huge quantities of natural resources, and the production of its cement component alone emits about 8% of all man-made CO2, roughly one ton per ton.

The status quo does not make any economic or environmental sense. Which begs the question, can we design our concrete structures to look after themselves? This way, they could last so much longer, we would use far less concrete, slashing expenditure, carbon emissions, and environmental damage.

Looking to natural systems for inspiration, the concept of self-healing materials emerged. So, can we turn the non-living concrete all around us into living systems? Wee see advances in other sectors. Self-healing paints for our cars, and self-healing asphalt for our roads are becoming a reality.

But concrete is a far more complex material. It is a multi-component, multi-layered system, and damage occurs at different length and temporal scales. As pat of a national team, our inspiration came from the similarly complex way in which our skin deals with damage at different levels.

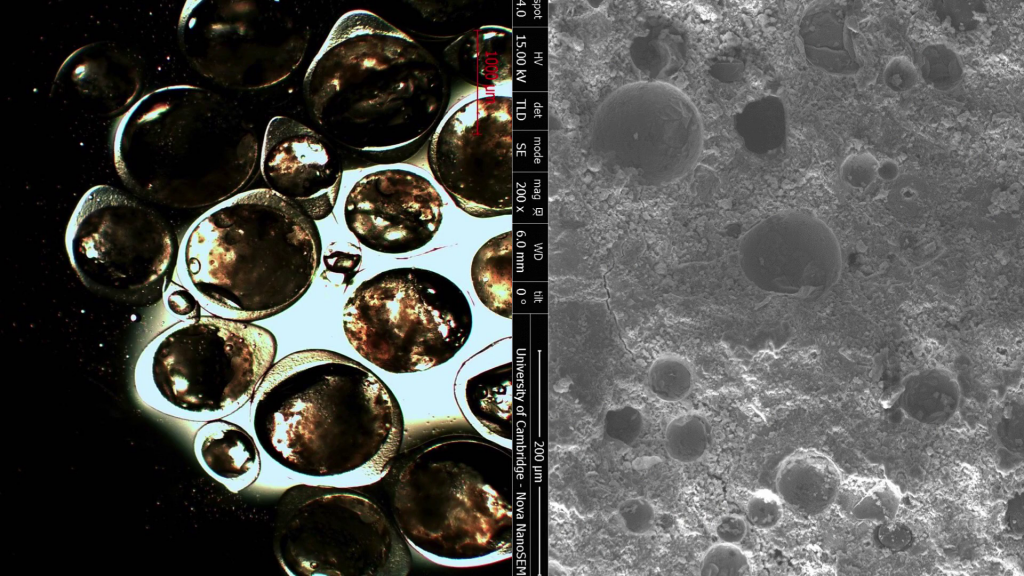

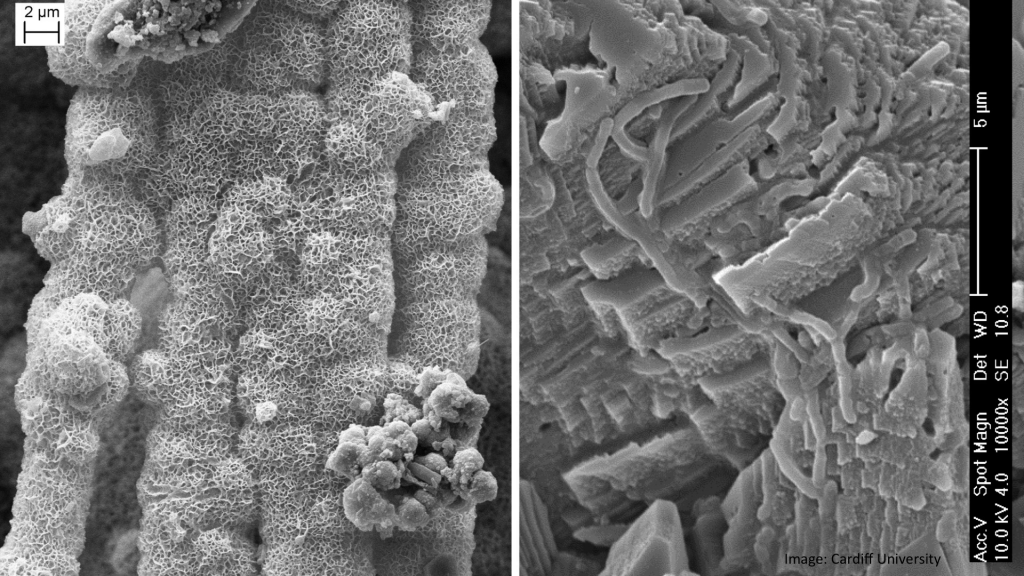

So for small-scale damage, my team at Cambridge has been developing tiny capsules which we felt with a healing agent and we mixed within the concrete. They then remain dormant until the concrete is attacked. A crack would them rupture the capsules, releasing the healing agent, which fills the crack, sealing it.

Similar to the formation of a blood clot, the whole of the self-healing process has to be compatible with a concrete matrix and to restore functionality, and we have been able to deliver a similar function using mineral compounds. Some strains of bacteria that produced limestone, which is a natural cement, is another good contender.

For large-scale damage, we are employing shape-memory polymers, the same materials used in medical sutures or shrink-wrap. These are plastic rods placed strategically within the concrete, and they shrink when large cracks form, thereby closing them, and the capsules can actually finish their sealing process.

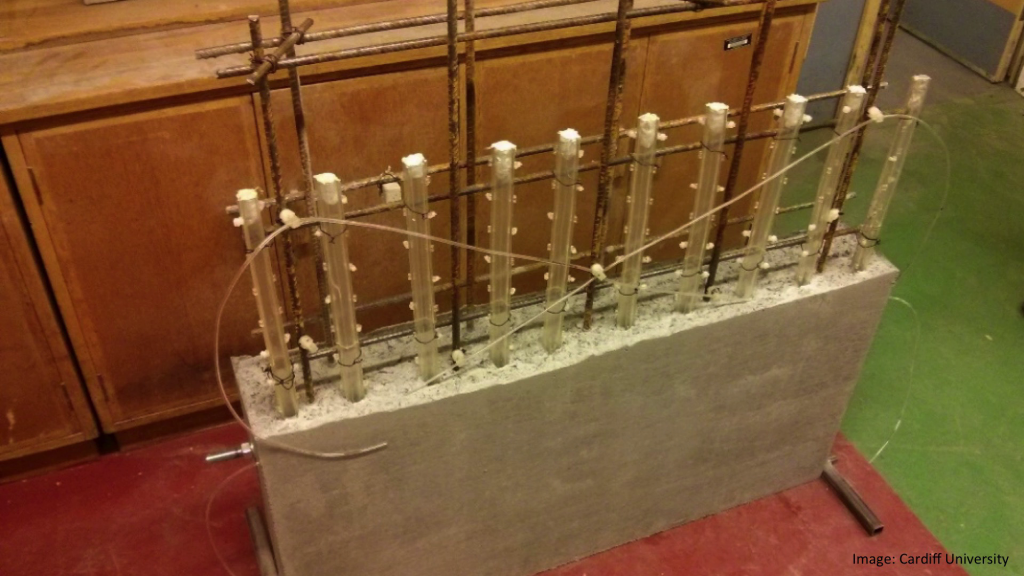

Now damage is sometimes recurrent. And like our circulatory blood system, we are developing flow networks using small interconnected tubes. Through these, we can continuously circulate a healing agent within the concrete so that it’s available when it’s needed again and again. So, we have made significant advances on the performance of individual self-healing components, and are collectively working on the more challenging integrated configurations.

There is also the challenge of longevity and resilience, as well as of course minimizing any additional capital cost of the concrete. Together with our industrial partners, we have conducted full-scale field trials through which we’re demonstrating some of the developed self-healing systems, and we are monitoring those in the real world. We are testing both concrete repair applications as well as new concrete construction.

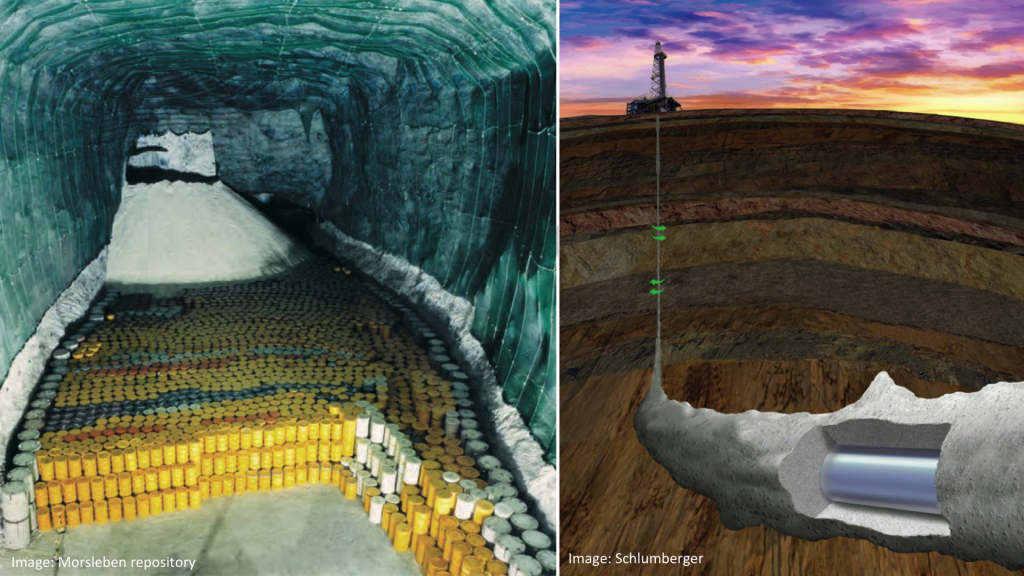

We are also impacting on other sectors where concrete and other similar materials like grouts and mortars play a key role. Our focus is on extreme and inaccessible environments, for example underground nuclear repositories, or in oil well cementing applications, where safety is paramount.

Self-healing concrete can deliver a low-carbon infrastructure by potentially eliminating inspection, repair, maintenance, and replacement, and building the future with a much lower whole-life cost. We can transform our landscapes and our everyday lives.

We are confident we can produce self-healing concrete, but it’s going to take a lot more than that to make it into a commercial reality. We are also exploring self-sensing, self-reporting, and self-immunity in concrete.

So my question to you is, how can we all work together to transform this remarkable construction material all around us into a far more remarkable living system? Thank you.

Further Reference

“The concrete that heals its own cracks ” by Abir Al-Tabbaa, at the World Economic Forum site.

Faculty page at the University of Cambridge.